Surface preparation

The key to success: high-quality surface preparation!

At Sixpro, our experts know how important it is to prepare metal surfaces before painting.

Why is it so critical? Surface preparation provides a perfectly clean surface to promote optimal paint adhesion.

Cleaning the surface eliminates dirt and impurities, like dust, oil and grease. It also removes scale and rust. The preparation process also roughs up the surface. This is an important step as paint doesn’t adhere well to smooth, flat surfaces. Lightly abrading the surface creates tiny peaks and dips that improve the application process.

This step is essential for all coating applications. Failing to prepare the surface can compromise the paint’s durability, making your parts more vulnerable to corrosion.

What are the different types of preparation?

Mechanical preparation

Mechanical preparation roughs up the surface to promote adhesion. It also eliminates the oxide layer. At Sixpro, we specialize in standard sandblasting and shotblasting.

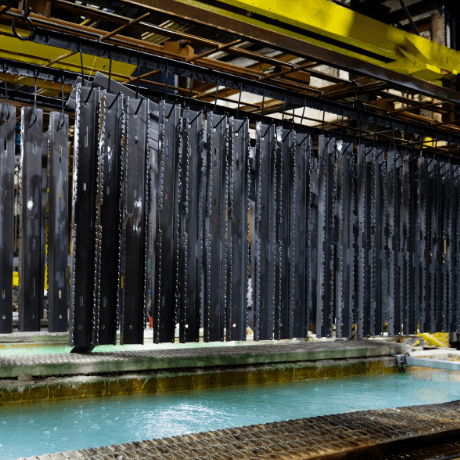

Chemical preparation

Chemical preparation consists of spraying or immersing metal products in chemical agents to increase corrosion resistance and promote paint adhesion. At Sixpro, we recommend our zinc phosphate treatment. Suitable for ferrous metals, zinc phosphate is an ideal alternative to the toxic materials once used in the industry.

Our team of professionals uses four key surface preparation processes:

- Sanding

- Shotblasting

- Sandblasting

- Zinc phosphate

Contact us to learn more.

We’ll answer your questions

Need information about our services or a quote for a project? Contact us.

"*" indicates required fields